The Old Datsun Racecar

Datsun 280Z Build: Five Years of Blood, Sweat, and Pain

When I picked up my Datsun 280Z five years ago, it wasn’t a car, it was a shell. Three engines, three transmissions, and a pile of mismatched parts. Most people would’ve passed, but I saw potential. That project became one of the most rewarding (and humbling) builds I ever took on.

Starting from a Shell

The car came with boxes of OEM parts, but I knew from the start it wasn’t going back to stock. I sold off the entire factory interior to help fund performance parts — everything from the seats to the dash.

In its place, I built a lightweight setup with an aluminum dash, Bride seats, Planted Technologies seat rails, and a race harness. The rear interior was gutted to make room for a fuel cell. Every decision was made with one goal in mind — turn it into a proper track-capable street car.

Engine and Drivetrain

The car originally came with multiple L-series engines, but I decided to sell them all to fund the one I really wanted — a OEM Nissan L28, rebuilt by Nissan in the 1990s and still sealed in the crate.

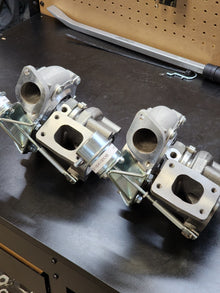

I struggled for a while after deleting the EFI and running SU carbs, tuning them endlessly with little consistency. Then I came across a deal I couldn’t pass up — a set of Nismo Mikuni triple carbs. They transformed the engine. Throttle response sharpened up, the idle stabilized, and the sound at wide open throttle was unlike anything else.

Power went through a Datsun Competition racing transmission, paired with Wilwood external-reservoir master and slave cylinders for smoother clutch engagement. It was an old-school setup that felt absolutely mechanical in the best way.

Suspension and Brakes

Stopping and handling were just as important as power. I upgraded the front brakes to a Toyota 4x4 big brake setup, running 300ZX rotors and Toyota calipers. The rear drums got Nismo racing shoes, and despite what people say, they held up surprisingly well for track use.

For suspension, I ran Silvermine coilovers, paired with Cusco front and rear strut bars to tighten up the chassis. The car cornered flat and felt planted, even under hard braking.

Aero and Exterior

I kept the exterior simple and functional. The car ran a Skillard Automotive front splitter for downforce and a BRE-style rear wing for stability at high speed. Nothing flashy, just purposeful.

Track Debut at Thompson Speedway

After years of building, the day finally came to get the car out on track. I took it to Thompson Motor Speedway for a shakedown and break-in day — and brought Matt from Matt’s Power House along to provide full trackside support, a service he offers regularly for racers and enthusiasts.

At first, I fought some fuel slosh and alignment issues, but once those were sorted out, the car came alive. Every lap got faster, and by the end of the day, it felt dialed in — all the late nights, busted knuckles, and trial-and-error paid off.

Where It Ended

Not long after that track day, I made the tough decision to sell the 280Z. That sale helped fund the start of my Ultra Power Market shop and my current BNR32 GT-R project — the next chapter of the story.

That Datsun taught me nearly everything I know about building, troubleshooting, and perfecting a car from the ground up.

Interested in Datsun Parts?

Not all of my Datsun parts are listed on my website, but they’re available through my eBay store.

If you’re building your own 240Z, 260Z, or 280Z, reach out through the Contact tab, and I’ll send you the link directly. I’ve sourced and tested a ton of parts for these cars — I’m always happy to help fellow Datsun builders keep theirs alive.